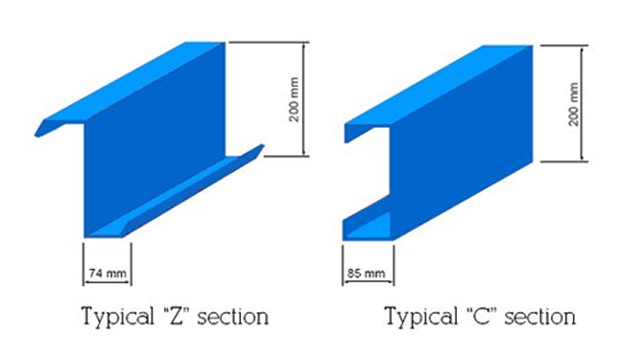

C or Z Shape Purline Forming Machine can produce many size of C & Z shape purline. The whole line mainly consists of uncoiler and its base, coil sheet flattening equipment, C & Z shape forming system, punching equipment, post-cutting equipment, hydraulic station, and controlling system.

C & Z Purlin mainly use hot roll steel strip or hot dip galvanized steel strip at thickness 1.5-3.2mm. It is roll formed by C or Z shape roll forming machine

Working Flow

Decoiling the Sheet → Sheet Guiding → Coil Strip Leveling → Roll Forming → Punching for horizontal hole → Punching for vertical hole → Measure Length → Cutting the Panel → Panels to the Supporter.

Product feature and usage

The products of C or Z shape purlin forming machine have excellent anti-bending property and are easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Applicable Area

Door Frame, Rack, Angle, Pallet Rack, Pack Post, Swage Beam Panel, Glass Wool Panel, Hoist Rail, Hand Rail, Car Molding, C-channel, Fire Shatter, M-bar, U-channel