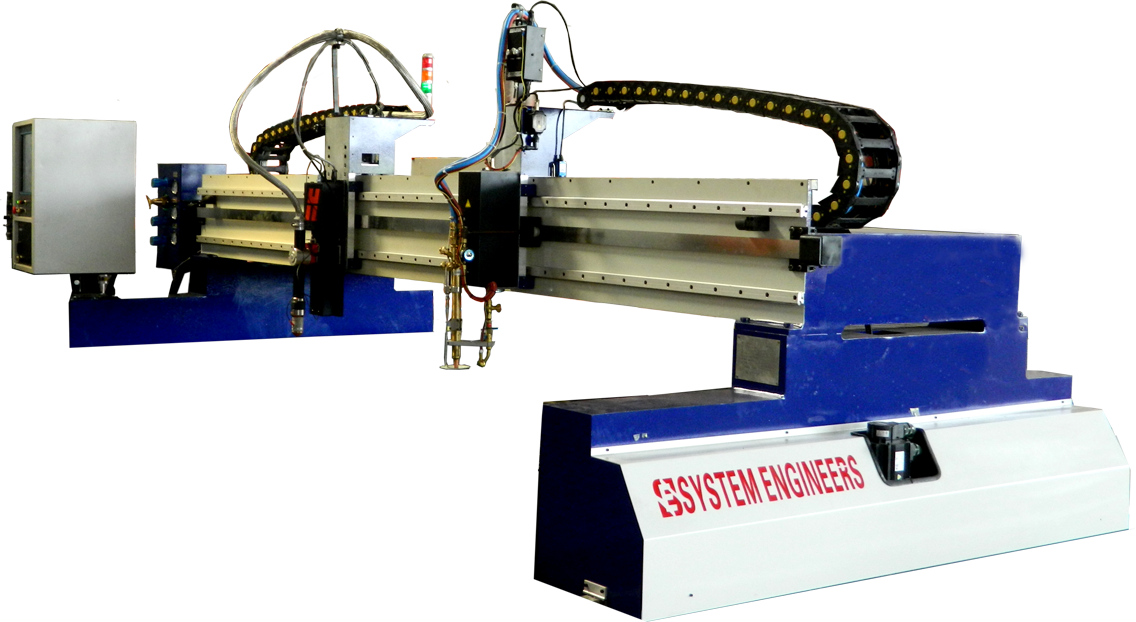

This machine is used for facilitating the process of plasma cutting, wherein electrically conductive materials are cut through by means of an accelerated jet of hot plasma. Moreover, due to its high speed and precision cut makes it a popular choice for applications in large scale industries to small hobbyist shops.

Moreover, it is tested over different quality parameters under the guidance of experts. Further, CNC Plasma Profile Cutting Machine is operated by means of a computer, wherein materials meet precise specifications by following programmed instructions.