Hypertherm, a U.S. based manufacturer of plasma, laser, and waterjet cutting systems introduce an entirely new class of plasma called X-Definition.

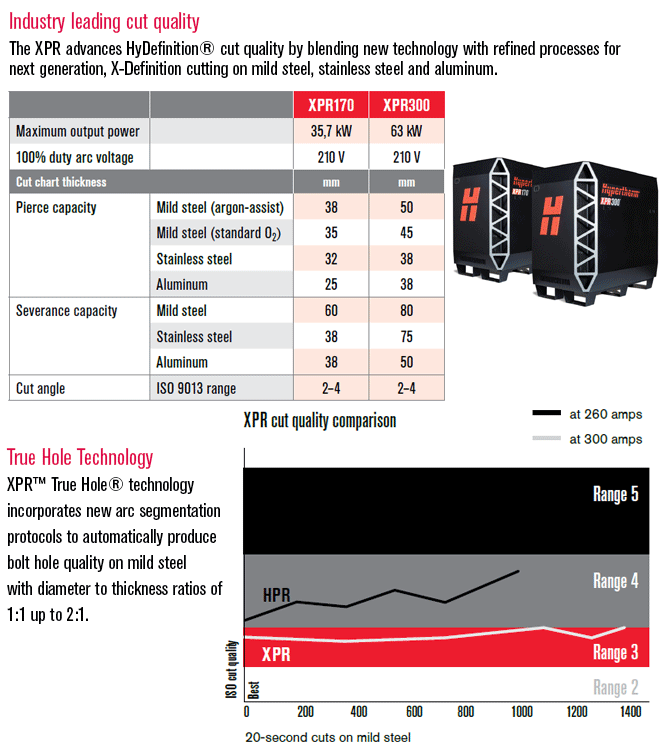

X-Definition class plasma combines engineering advances and refined high definition plasma processes to deliver unmatched plasma cut quality on mild steel, stainless steel, and aluminum.

The XPR Series cuts faster and uses power more efficiently than earlier Hypertherm systems. Piercing capability is also improved. Additionally, consumable life and cut quality over the life of the consumables get a dramatic boost from advances such as Cool Nozzle and Arc Response Technology.

XPR300 INCREASE THE PRODUCTIVITY

Yes, The XPR300 has the potential to increases the productivity

- Higher quality cuts that reduce or eliminate secondary operations

- Increased cut speeds on thicker materials.

- Dramatic improvement in consumable life on mild steel applications with quicker set-up time.

- Thicker piercing capability than other plasma systems on the market.

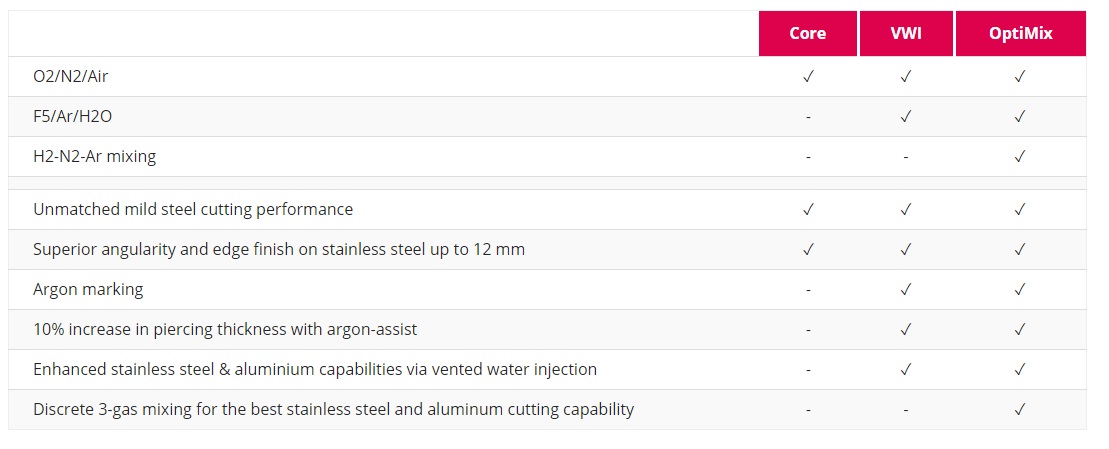

DIFFERENCE BETWEEN THE 3 AVAILABLE GAS CONNECT CONSOLES

Hypertherm offers three state-of-the-art console options to combine with the XPR300. (Core, VWI and Optimix)

The difference between these gas consoles is the ability to mix more gases/fluids. These extra processes are beneficial if your business wants to cut up to 50 mm mild steel or requires enhanced quality on stainless steel or aluminium.

The most basic gas console is the Core, which can mix N2, O2 and Air. It is an excellent choice if you mostly want to cut high-quality holes in mild steel up to 45 mm and stainless steel up to 12 mm. For thin stainless steel, the edge finish is brighter as no air is mixed in the plasma gas. Nitrogen is used for marking which gives a basic finish.

A more sophisticated console is the Vented Water Injection (VWI). Besides mixing N2/O2 and Air, VWI also allows you to mix F5/Ar/H2O. The benefits of argon include a 10% increase in piercing thickness and better marking capabilities. The F5 process with H2O shield will deliver significantly better results on non-ferrous materials like stainless steel and aluminium. Some of the processes use water and if these processes are required, special care must be taken when selecting the cutting table and filter.

The premium gas console is the Optimix. It offers all the capabilities of the Core and VWI consoles plus discrete 3-gas mixing (Ar, H2, and N2) for the best plasma cutting results on stainless steel and aluminium.

In the table below, you find an overview of the capabilities of the three gas consoles. If you are not sure which gas console is best for your business, you can always ask your machine manufacturer for an expert opinion.